Regulated airguns (PCP/pre-charged pneumatic) represent the pinnacle of airgun technology, with pressure regulation systems ensuring consistent performance. Unlike unregulated models that experience significant velocity drops as air pressure decreases, regulated guns maintain near-identical energy output shot-to-shot. This article examines why regulated systems outperform traditional designs, answering critical technical questions for serious shooters.

How Airguns Work: The Basics

At its core, a pre-charged pneumatic (PCP) air rifle operates by storing compressed air in a reservoir, typically at pressures between 2000-3600 psi (138-248 bar). When the trigger is pulled, a precise amount of this compressed air is released behind the pellet, propelling it through the barrel.

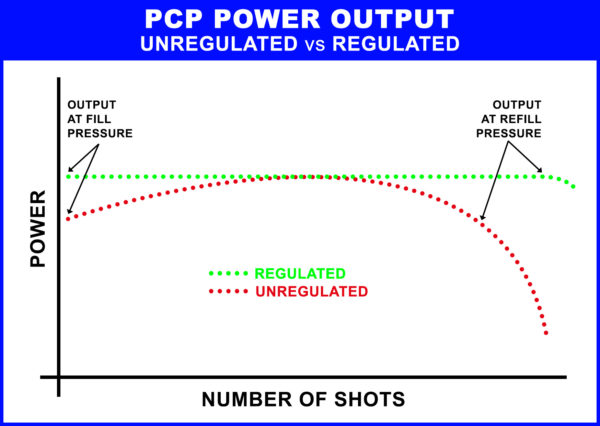

In unregulated PCP rifles, the pressure behind each shot gradually decreases as the reservoir depletes. This means the first shot from a full tank might use air at 3000 psi, while the twentieth shot might use air at 2700 psi. This pressure differential directly affects pellet velocity, trajectory, and ultimately, accuracy.

All PCP air gun operate on these principles:

1. Air Reservoir: Stores compressed air (typically 200-300 bar)

2. Valve System: Releases measured air bursts when triggered

3. Hammer Spring: Strikes the valve to initiate firing

4. Projectile Acceleration: Air pressure propels pellets through the barrel

A regulator functions as an internal "valve" that meters air from the main reservoir to a smaller regulated chamber at a consistent pressure, regardless of the main tank's pressure (until it falls below the regulator's set point). This ensures that each shot receives the same driving force, resulting in consistent velocities.

Unregulated systems see pressure fluctuations directly transmitted to the valve, causing velocity variations. Regulated guns insert a secondary chamber between the reservoir and valve, maintaining stable pressure regardless of tank levels.

Measuring Regulated Pressure: Tools & Techniques

Essential Equipment:

- Pressure Gauge: Monitors regulator output (e.g., 100-150 bar setting)

- Chronograph: Tracks muzzle velocity (±1% variation indicates proper regulation)

- Shot Count Tracker: Logs consistency over multiple firings

Benchmark Testing Protocol:

1. Fill reservoir to maximum pressure

2. Fire 20 shots to stabilize the regulator

3. Record velocities from shots 21-50

4. Calculate extreme spread (ES) and standard deviation (SD)

- Regulated: ES <30 fps, SD <10 fps

- Unregulated: ES >80 fps, SD >25 fps

How Regulation Enhances Accuracy: Physics in Action

The primary advantage of regulated systems is shot-to-shot consistency. Research has demonstrated that well-regulated PCP rifles can maintain velocity variations within ±3 fps (feet per second) throughout most of their usable shot count, while unregulated systems might experience variations of 20-30 fps or more across their power curve. Three critical accuracy factors improved by regulation:

| 1. Vertical Dispersion Reduction | - Unregulated guns lose 1.5-2" elevation at 50 yards as pressure drops - Regulated systems maintain <0.5" vertical spread |

| 2. Consistent Barrel Time | - Pellet dwell time variation: ±0.02ms (regulated) vs. ±0.15ms (unregulated) - Stabilizes harmonic vibrations for repeatable harmonics |

| 3. Shot Cycle Uniformity | - Recoil impulse variation: ±5% (regulated) vs. ±30% (unregulated) - Minimates shooter anticipation errors |

Case study: Pinty P-Force Series

Pinty P-Force Bullpup 9 Pellet .22Cal PCP Air Gun High Power, Pros: Regulated, metal rails, light weight, accurate, huge shot count per fill, over-trigger side lever, nearly silent, compact, 900fps+ with 14.3 gr pellets, comes with spare o-rings and silicone grease, spring loaded auto-closing fill port cover. It can be used for Small Game Hunting Shooting.

This consistency translates directly to improved accuracy, particularly at longer ranges. Consider a .22 caliber pellet traveling at 900 fps: a 15 fps velocity variation can result in nearly an inch of vertical point-of-impact shift at 50 yards. For competitive shooters or hunters requiring precise shot placement, this consistency is invaluable.

Additionally, regulated systems typically deliver more usable shots per fill. While an unregulated rifle might provide 30 "optimal" shots before velocity drops significantly, a regulated version of the same rifle might deliver 60+ shots within an acceptable velocity window, effectively doubling the practical shot count between refills.

Regulator Adjustment Considerations

Warning: Improper adjustment voids warranties and risks damage, proper adjustment requires specialized knowledge and equipment.

Adjusting Regulators: A Step-by-Step Guide

Tools Required:

- Regulator adjustment tool (brand-specific)

- Digital pressure gauge

- Hex key set

Adjustment Process:

1. Safely depressurize the airgun completely

2. Access regulator via air cylinder or stock compartment

3. Adjusting the regulator spring tension. Turn clockwise (increase pressure) or counterclockwise (decrease): - 1/4 turn ≈ 10-15 bar change

4. Reassemble and test-fire with chronograph

5. Fine-tune in 1/8-turn increments until desired velocity stabilizes

Most manufacturers calibrate regulators to optimal settings for the specific rifle design, and improper adjustment can damage components or create unsafe conditions. For this reason, many warranties explicitly exclude damage resulting from regulator adjustments.

For those determined to modify regulator settings, incremental adjustments followed by comprehensive chronograph testing are essential. Most experts recommend changes of no more than ¼ turn at a time, followed by at least 20 shots to allow the system to stabilize before evaluation.

Optimal Pressure Ranges:

| Caliber | Ideal Reg Pressure | Velocity Target |

| .177 | 80-110 bar | 900-1000 fps |

| .22 | 100-130 bar | 850-920 fps |

| .25 | 120-150 bar | 800-880 fps |

Between Regulation & Pellet Selection

Since the air pressure remains consistent, subtle variations in pellet weight, shape, and fit become more apparent in grouping performance. Regulators allow precise matching of pressure to projectile characteristics:

Light Pellets (14-16gr):

- Lower pressure (80-100 bar) prevents overspin/instability

- Higher pressure causes spiraling beyond 40 yards

Heavy Slugs (25-34gr):

- Requires 130-160 bar for optimal stabilization

- Insufficient pressure increases transonic turbulence

Hybrid Tuning Example:

- NSA 24.8gr slug @ 150 bar → 890 fps (0.65 BC)

- JSB 25.4gr pellet @ 130 bar → 865 fps (0.047 BC)

The ideal approach involves testing multiple premium pellet brands and weights once the regulation system is properly tuned. Chronograph testing should show minimal standard deviation numbers (ideally below 3 fps) with the optimal pellet type.

Does Regulator Pressure Drift Over Time?

All regulators experience gradual performance changes over time:

1. Regulator Seals Degradation:

The rubber O-rings and seals within regulators can harden or deform over time, potentially altering regulation pressure or causing leaks.

- Typical lifespan: 10,000-15,000 shots (Buna-N O-rings)

- Symptoms: Pressure drop >5% between refills

2. Creep:

The regulator spring can weaken slightly after thousands of cycles, gradually reducing regulated pressure.

- High-end regulators: <2 bar/hour

- Budget models: Up to 10 bar/hour

3. Temperature Sensitivity:

Most regulators will show slight pressure variations with significant temperature changes (typically 1-2 psi per degree Fahrenheit).

- Aluminum regulators: 0.3 bar/°C

- Stainless regulators: 0.1 bar/°C

Maintenance Schedule:

Regular chronograph verification (every 6-12 months) can identify any drift in regulated pressure, allowing for timely maintenance.

- Annual rebuild for casual shooters (<5,000 shots)

- Biannual service for competitors (>15,000 shots)

Conclusion

Regulated airguns transform shooting experiences through engineering excellence. By maintaining consistent operating pressures, they eliminate the largest variable in ballistic performance - enabling sub-MOA accuracy that rivals firearm precision. While requiring greater initial investment and maintenance, regulated systems reward users with unmatched repeatability across hunting, competition, and scientific applications.

Pro Tip: Always pair regulated airguns with high-quality projectiles and lubricants - the system’s consistency will amplify both good and poor ammunition choices.